W.Nr. 1.6562 Alloy Steel Round Bar 4340 SNCM439 Forged Rod Normalized Annealed Quenched

AISI/ASTM 4340 Alloy Steel Round Bar SAE AISI 4340 Steel Properties, Heat Treatment SAE4340 Alloy Steel

40CrMnNiMo8-4 is another alloy which displays superior mechanical properties. This material is available in the Annealed or Quenched and Tempered conditions. 4340 is used many industries including oil and gas exploration, gear manufactring etc.

Comparable Standards:

| AISI/SAE |

DIN |

W.Nr. |

AFNOR |

JIS |

BS |

SIAU |

GB,YB |

| 4340 |

40CrMnNiMo8-4 |

1.6562 |

- |

SNCM439 |

- |

NCM4 |

40CrNiMoA |

Chemical Analysis (%):

| C |

Mn |

Si |

Cr |

Ni |

Mo |

P |

S |

| 0.37-0.44 |

0.50-0.80 |

0.15-0.40 |

0.60-0.90 |

1.60-1.90 |

0.20-0.30 |

≤0.035 |

≤0.040 |

Mechanical properties

| Tensile str. (N/mm2) |

Yield point (N/mm2) |

Elongation (%) |

Contraction (%) |

Impack work (J/cm2) |

Hardness (HB) |

| 980 |

835 |

12 |

205 |

55 |

269 |

| Heat Treatment(°C) |

Physical Properties |

| Quenched |

Tempered |

Thermal Conductivity

(20°C)Wm-1. ok-1 |

Typical Thermal expansion coefficient (20-200°C) |

Specific Heat

(20°C) |

Density

(20°C) |

| 850 |

600 |

12 |

12.7 |

|

|

AISI 4340 Alloy Steel Round Bar

Applications:

- AISI 4340 Alloy Steel Used for manufacture big sized important Quenched-and-Tempered parts which request good toughness and high strength. Such as top load shaft in heavy-duty machinery.

- AISI 4340 Alloy Steel Used for steam turbine shaft, vane, and heavy-load transmission parts, fastening piece, crankshaft, gears etc. With diameter is biger than 250mm.

Description:

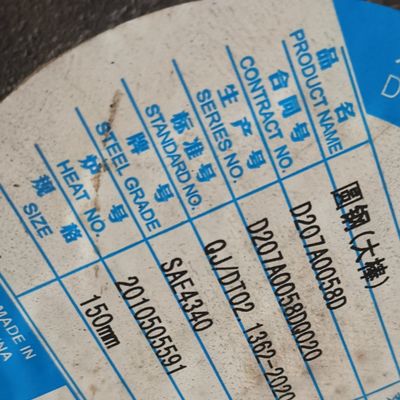

1. AISI 4340/GB40CrNiMo/DIN 1.6511 alloy steel round bar

2. Hot rolled or forged condition, annealing, black or milled surface

3. Hardness: ≤220HBS;

4. Hot rolled technology: EAF+LF+VD

Forged technology: EAF+LF+VD+ESR+Forging +Q T + Machined surface

5. Ultrasonic test standard: SPE1921-GR3, CLASS D/D or E/E

6. Production leadtime: 7~10 days

Competitive Advantage:

- High strength,

- High tenacity

- Good hardenability

- High resistance to thermal properties.

- Competitive price

- Fast production leadtime

- All the material are inspected with 3 times to meet the highly standards

MITTEL Specializes in plastic mould steel, hot work mould steel,

cold work mould steel alloy steel and carbon structural steel, such as: P20, P20+Ni, 1.2714,

1.2083, 1.2316, H13, O1, D2, D3, D5, 1045, 1050, A3, 52100(EN31), 4137, 4140, 4340,

5140, 6150, 8620 and SCM420 for exporting over 20 countries now, such as: Brazil, India,

Turkey, Italy, Germany, Korea, Malaysia, Iran and so on.

Our company have introduced large-sized Vertical saw machines, horizontal saw machines,

Milling machines, Grinding machines and other advance equipments, we can export our

products by wholesales and retail sales, whole plate or strip is available. All our products

can meet the standards of DIN, AISI, JIS and GB, all the material should be inspected the

ultrasonic, hardness and others strict inspection process before the shipment!

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory and trading company

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!