Product name

|

Super Duplex Stainless steel Bar UNS32760 ASTM A789

|

Process method

|

Cold drawn/cold pilgered

|

Surface finish

|

Annealed/cold pilgered/manual polished/mechanical polished

|

Material

|

UNS32760, UNS32750

|

Standards

|

ASTM A182

|

Size

|

Diameter: 4mm~800mm Length: Max. 16 meters

|

Applications

|

For heater exchanger, condenser

|

Material Specification

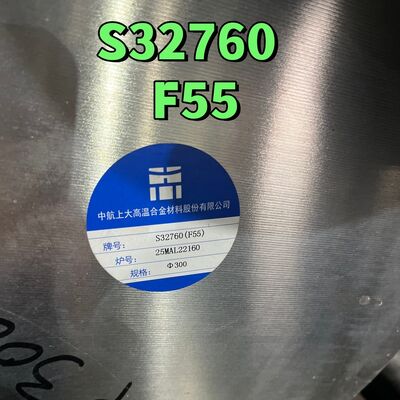

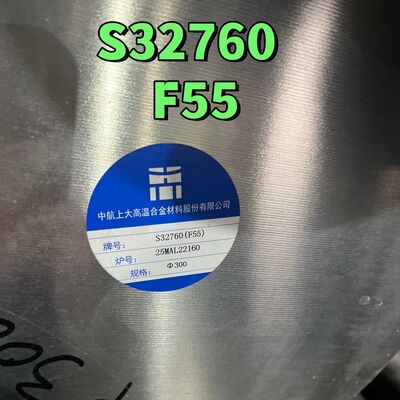

S32760, also called F55 or 1.4501, is a high-alloy super duplex stainless steel, featuring strong strength and corrosion resistance, mainly used in a variety of strong corrosion environments such as chemical processing, petrochemical and submarine equipment.

Chemical Composition of S32760 Super Duplex Stainless Steel

| |

Ni |

Cr |

Mo |

Mn |

Cu |

Si |

C |

N |

S |

P |

W |

Fe |

| MIN |

6.0 |

24.0 |

3.0 |

- |

0.5 |

- |

- |

0.2 |

- |

- |

0.5 |

- |

| MAX |

8.0 |

26.0 |

4.0 |

1.0 |

1.0 |

1.0 |

0.03 |

0.3 |

0.01 |

0.03 |

1.0 |

Balance |

Features of S32760 Super Duplex Stainless Steel

S32760 duplex steel also features strong resistance to chloride corrosion, high thermal conductivity and low coefficient of thermal expansion. Higher chromium, molybdenum and nitrogen content make it highly resistant to pitting, crevice corrosion and other corrosions. The excellent overall performance of S32760 duplex steel is superior to that of general dual phase steel, such as 2205, S31803 and so on.

S32760 duplex steel is resistant to various inorganic acids and organic acids. The copper added makes it resistant to non-oxidative acid corrosion. S32760 is also resistant to strong alkali corrosion, but it is not suitable to work at temperatures above 300 ° C for a long time, because a long-term exposure to such high temperature will lead to reduced toughness of the material.

S32760 stainless steel was used as cast steel in the early 1980s to make up the insufficient corrosion resistance of the second-generation duplex stainless steel 00Cr22Ni5Mo2N (2205). In the late 1980s, it came to be used as the deformable material for pipeline systems. Subsequently, this super duplex was introduced as an important corrosion-resistant material into oil and gas development, seawater environment, flue gas desulfurization (FGD), desalination, and chemical applications.

S32760 stainless steel also contains a small amount of tungsten and copper in addition to high chromium, molybdenum and nitrogen. In early times, tungsten and copper were added to improve the casting properties of this alloy. Later, it was found that tungsten and copper could enhance the corrosion resistance of the steel in certain acids and its ability to passivate in seawater.

Just like other super duplex stainless steels, S32760 stainless steel microstructure presents a two-phase structure with α/γ close to 1 under solid solution conditions. However, undergoing from high temperature to room temperature like incorrect thermal processing, heat treatment and welding process, during which cooling processes, there will be intermetallic phases and nitrides on the substrate of S32760 stainless steel. When exposed to temperature at around 900 °C for more than 100 seconds, σ, χ, Cr2N, etc. will precipitate on the substrate; at about 475 °C for more than 800 seconds, the α phase will precipitate. In order to avoid the precipitation of the intermetallic phase and the Cr2N phase, it must have a sufficient cooling rate during the cooling process. Plus, this super duplex stainless steel does not adapt to heat treatment and cooling to produce σ phase.

S32760 Super Duplex Stainless Steel Applications

- 1) Neutral chloride environment;

- 2) Oil refining industry;

- 3) Pipeline used for chemical industry;

- 4) Oil and gas industry;

- 5) Pulp and paper industry;

- 6) Fertilizer industry, urea industry, phosphate fertilizer industry;

- 7) Seawater environment, energy and environmental protection industry;

- 8) Light industry and food industry, food and pharmaceutical industry equipment;

- 9) High strength structural parts;

- 10) Hood desulfurization, infiltration desalination equipment, sulfuric acid plant;

- 11) Submarine pipelines, marine engineering fasteners, etc.;

- 12) Others.

Products Show

Why Choose

Rich experience

We have been engaged in machining for 10 years. Our company had good reputation with customers from American, Europe, North America, and Australia, India etc. We also have a good team for sale and quality control.

Good service

We will respond to you within 24 hours. We manufacture non-standard parts according to your drawings. And we will continue to serve you after sales and will be responsible for the mistakes from us.

Low price

The prices of our production are reasonable! The prices will be much better if your quantity is good.

Pefect quality

We have strict quality control from producing to delivery. Our company had strong technology support, 80% of our colleagues are master or bachelor's degree. We have cultivated a group of managers who are familiar with product quality, good at modern concept of management.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!